Before starting our article, please do not forget to review the following pages of Durfoam:

- physically cross linked polyethylene foam types

- chemically cross linked polyethylene foam types

- polyethylene foam types

Have you ever witnessed an explosion of innovation that redefines entire industries? Enter cross-linked polyethylene foam – the game-changer that is reshaping the landscape of various sectors. This versatile material is not just making waves; it’s creating a tsunami of possibilities across packaging, insulation, automotive, and construction fields.

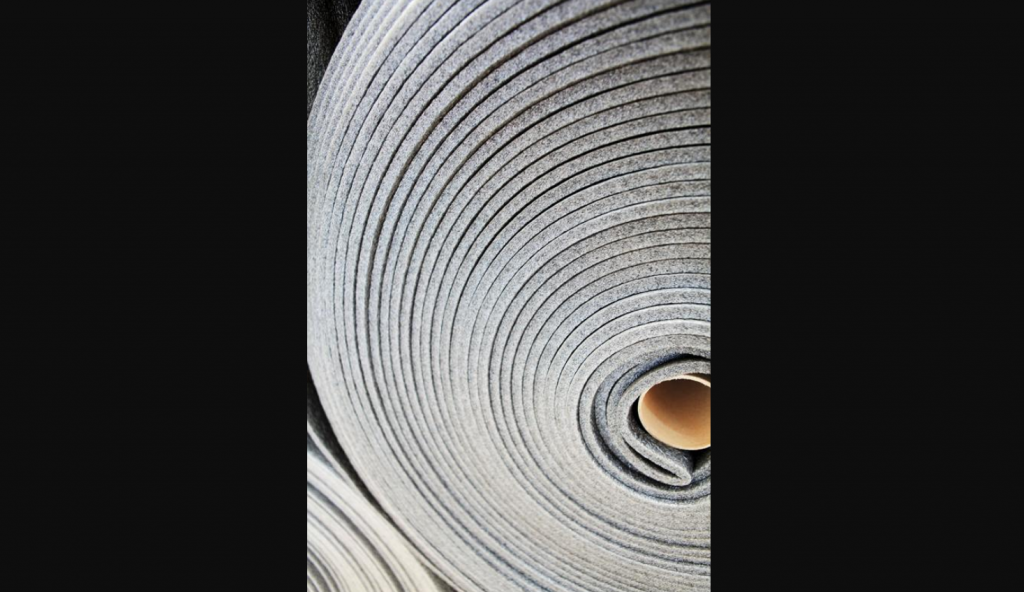

Imagine a material that combines the strength of a warrior with the flexibility of a gymnast. Cross-linked polyethylene foam boasts unparalleled durability, allowing it to withstand the toughest challenges while remaining supple and adaptable. Its water resistance is like a shield, protecting against moisture and ensuring longevity in diverse applications.

In the realm of packaging and insulation, cross-linked polyethylene foam is a superhero in disguise. It revolutionizes the way products are protected during transit, providing a cushioning effect that safeguards fragile items from the harshest journeys. As an insulation solution, it acts as a thermal barrier, keeping spaces cozy in winter and cool in summer.

Now, let’s shift gears to the automotive and construction sectors, where cross-linked polyethylene foam is the unsung hero behind the scenes. From enhancing safety features in vehicles to improving energy efficiency in buildings, this material is a silent force driving progress. In automotive components, it absorbs impact like a shield, ensuring passengers are cocooned in safety. In construction materials, it acts as a silent guardian, fortifying structures against the elements.

Properties of Cross-Linked Polyethylene Foam

Cross-linked polyethylene foam boasts a remarkable set of properties that set it apart from other materials in the industry. Its unique characteristics make it a preferred choice in a wide range of applications. Firstly, the durability of cross-linked polyethylene foam is outstanding, ensuring long-lasting performance even in demanding environments. This durability makes it ideal for use in industries where reliability is key.

Secondly, the flexibility of cross-linked polyethylene foam is a major advantage. It can conform to various shapes and contours, providing excellent cushioning and protection. This flexibility allows for versatile applications across different sectors, from packaging to automotive.

Moreover, the water resistance of cross-linked polyethylene foam is highly beneficial. This property prevents water absorption, making it suitable for use in wet or humid conditions. The water-resistant nature of the foam ensures that it maintains its integrity and performance over time.

Additionally, the thermal insulation properties of cross-linked polyethylene foam make it an excellent choice for applications where temperature control is crucial. Whether used for insulating buildings or protecting sensitive equipment, this foam provides reliable thermal insulation, contributing to energy efficiency.

In conclusion, the properties of cross-linked polyethylene foam, including durability, flexibility, water resistance, and thermal insulation, make it a versatile and valuable material for a wide range of industries. Its unique combination of features sets it apart as a top choice for various applications, redefining standards and driving innovation.

Applications in Packaging and Insulation

When it comes to applications in packaging and insulation, cross-linked polyethylene foam is truly a game-changer. This versatile material is reshaping the way we approach packaging solutions and insulation needs across various industries. Its unique properties and benefits make it a top choice for many businesses seeking reliable and efficient materials.

Cross-linked polyethylene foam excels in the packaging industry due to its exceptional cushioning and protective qualities. Whether it’s safeguarding fragile items during shipping or providing insulation for temperature-sensitive products, this foam delivers unmatched performance. Its ability to absorb shocks and vibrations makes it ideal for ensuring the safe transport of goods.

In the realm of insulation, cross-linked polyethylene foam stands out for its thermal and acoustic properties. By effectively trapping air within its closed-cell structure, this foam acts as a barrier against heat transfer, making it an excellent choice for insulating buildings and appliances. Its water resistance further enhances its durability and longevity in various environments.

Moreover, the lightweight nature of cross-linked polyethylene foam makes it easy to handle and install, reducing labor costs and improving overall efficiency in packaging and insulation applications. Its flexibility allows it to conform to different shapes and surfaces, ensuring a snug fit that maximizes its insulating capabilities.

Businesses across the globe are turning to cross-linked polyethylene foam for their packaging and insulation needs, recognizing its unparalleled performance and cost-effectiveness. Whether it’s protecting valuable products during transit or maintaining optimal temperatures in residential or commercial spaces, this innovative material continues to redefine standards in the industry.

Impact on Automotive and Construction Sectors

When it comes to the impact of cross-linked polyethylene foam on the automotive and construction sectors, the possibilities are truly explosive. Imagine a material that can enhance the safety, comfort, and energy efficiency of vehicles and buildings alike. This is where cross-linked polyethylene foam steps in as a game-changer, revolutionizing the way components are designed and constructed.

In the automotive industry, the lightweight yet durable nature of cross-linked polyethylene foam is reshaping the way vehicles are built. From reducing overall weight to improving sound insulation and vibration dampening, this material is a versatile solution for enhancing the driving experience. Additionally, its resistance to chemicals and oils makes it ideal for use in engine compartments and undercarriage components.

Furthermore, in the construction sector, the impact of cross-linked polyethylene foam is equally remarkable. By providing excellent thermal insulation properties, this foam helps in creating energy-efficient buildings that require less heating and cooling. Its flexibility and ease of installation make it a preferred choice for insulating pipes, HVAC systems, and structural elements.

Moreover, the use of cross-linked polyethylene foam in construction materials such as underlayment for flooring or as a protective layer in roofing systems adds an extra layer of durability and longevity to buildings. The material’s resistance to moisture and mold growth further ensures the longevity of structures, making it a sustainable choice for modern construction projects.